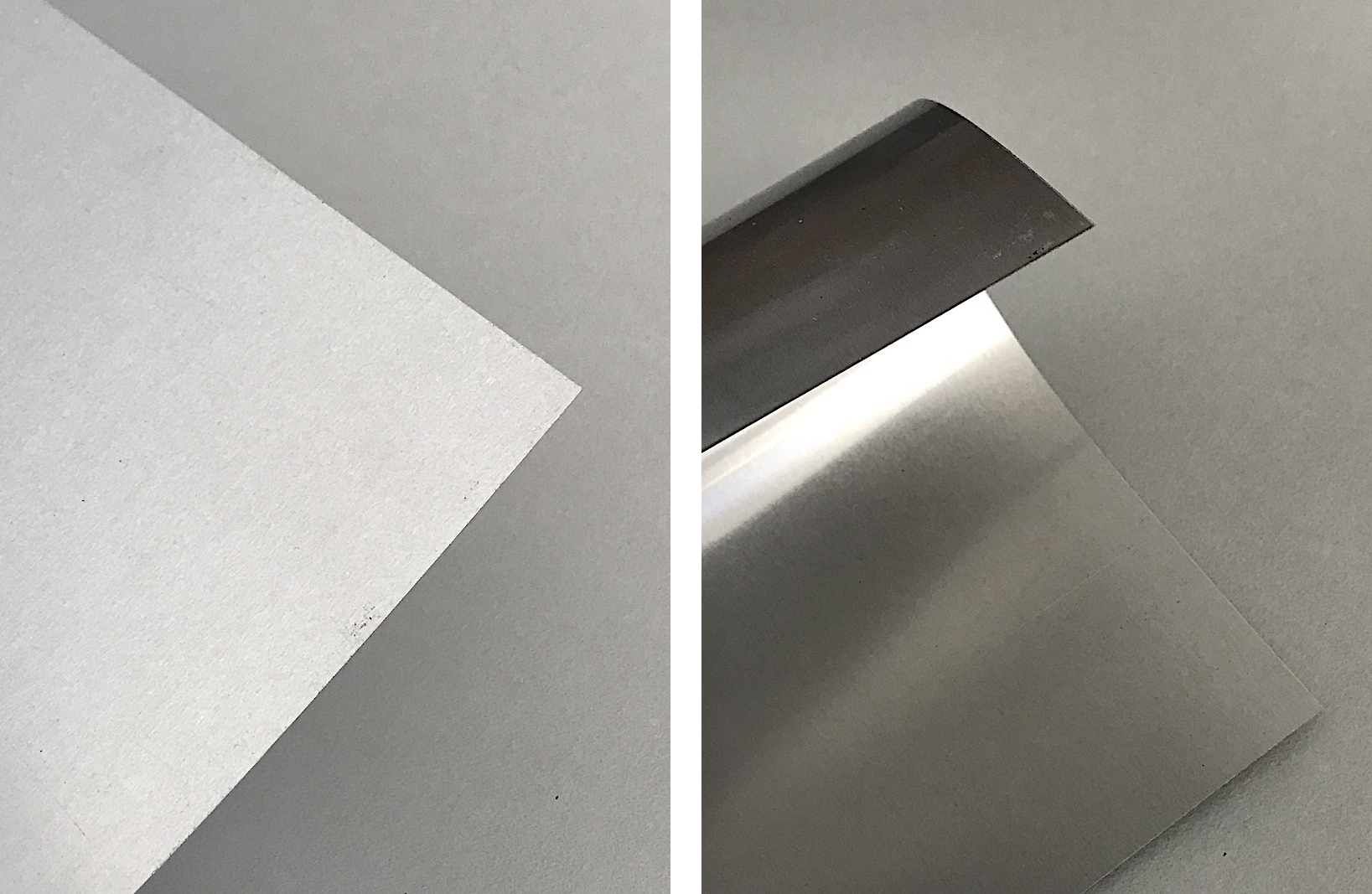

Metal Flashing

Above are examples of aluminum flashing acquired from a local hardware store. It has a brushed finish. One side appears glossier than the other, so it must have a clear coating on that side. It is springy, so it is hardened. A caliper reading shows that it is 0.008" to 0.009" thick, or 8 - 9 thousandths. This is equivalent to 31-32 gauge non-ferrous metal sheet. 80lb Bristol paper is 10 thousandths (ten thou) thick.

About flashing, primarily aluminum flashing

- Flashing is readily available at hardware stores, cuts easily with scissors, and has a large surface area to thickness ratio. It is appropriate for mobile airfoil elements. Because aluminum flashing is lightweight, it is ideal for making things that hang from a ceiling or above your head.

- The term, "flashing", refers to any thin material that is used in construction to prevent the passage of water at transition points on buildings.

- Hardware stores can have flashing made from a wide variety of materials, including aluminum, galvanized steel, and plastics. Copper, lead, brass, and zinc are also found in flashing form, but are specialty items. Be careful not to mistake galvanized steel for the aluminum. It is significantly heavier, and more difficult to work.

You may not have a choice in what you find, but their properties are noticeable. Manufacturer reps sometimes cannot even provide information on what types of aluminum flashing is sold where, or to even be aware that there are physical differences in their products. Here are some qualities of aluminum flashing you may encounter:

- plain (no coatings)

- coated (with a clear finish to prevent oxidation - you may not know this is there, other than an unusual smooth feeling, or a different kind of shininess on one side). Care must be taken when heating coated metal because it will produce a terrible odor, and will discolor to a caramel brown to uneven black.

- anodized one side (may look like artificial brass or gold)

- hardened (this feels very springy, and if you took one corner and bent gently with your fingers, it would snap back, best for maintaining a dent-free piece)

- dead soft (this can be easily bent by finger pressure on a corner, and the bend would stay in place, ideal for projects where deformation of the sheet is important)

- very thin or heavier gauge (this information may not be listed on the product)

- mill finish (dull, with no parallel scratches)

- brushed or sanded (with parallel scratches all along its length)