VEMCO, The World's Finest Compasses

Visit Lisa Jones' wesite here: thockmortonjones.com

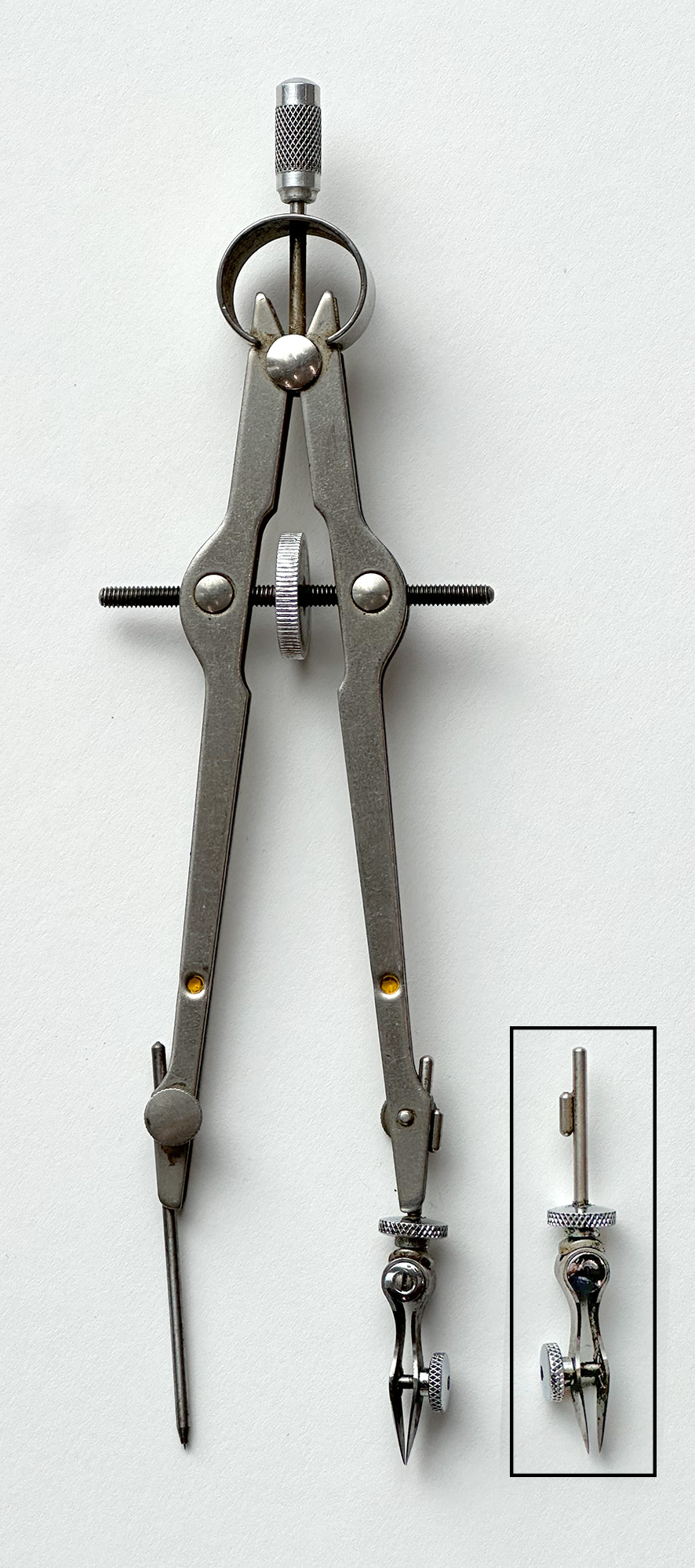

Designed and manufactured in Pasadena, California, VEMCO compasses have become my personal favorites among all compasses, as theirs were very lightweight, strong, precise, and visually unique. Innovation came in the form of a truss design that eliminated cast metal or heavily machined parts; instead, the legs were stamped, assembled, and resistance welded in two spots. These spots were where color was applied to make them Yellow, Red, or Blue Dot. The truss design yielded another benefit by applying a clamping force to the cylindrical nuts that engage with the center screw, keeping the compass from drifting out of its set radius. VEMCO compasses are a pleasure to hold, adjust, and use. In contrast, most other compasses are heavy, and - other than top of the line versions - are loose fitting, causing them to become out of adjustment during use or when set down. Contemporary compasses are in general poorly made, and if die cast, they are particularly egregious and do not function well starting at first use.

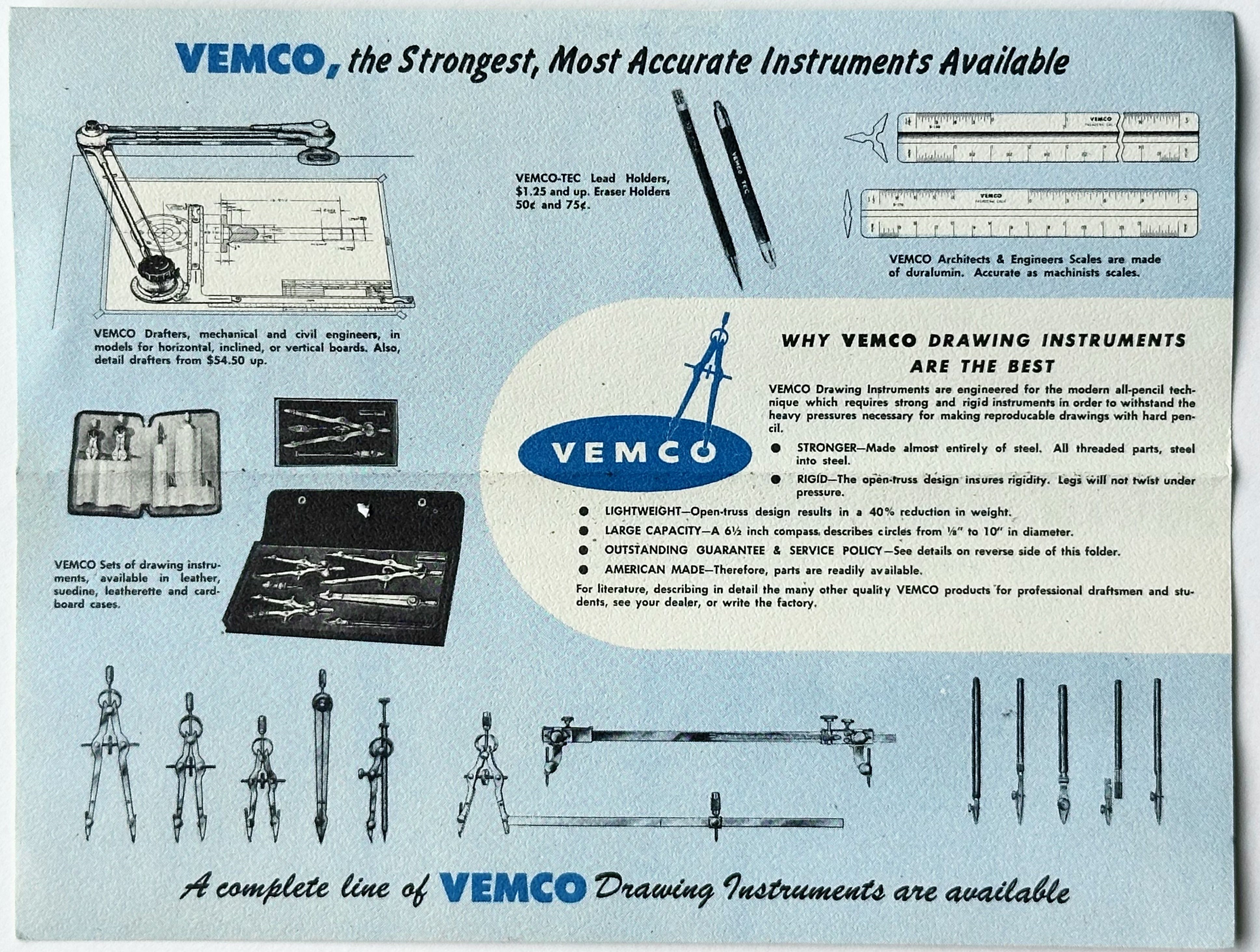

VEMCO made compasses, dividers, inking pens, and drafting machines. These instruments were critical in an era of expansive engineering, building, manufacturing and design before the age of readily available computers. This page focuses specifically on the innovations and uniqueness of Vemco's compasses and dividers. They sold these instruments in three grades in order to capture different markets. All grades performed beautifully, and could be used to high levels of precision, but there was a definite market for all three grades.

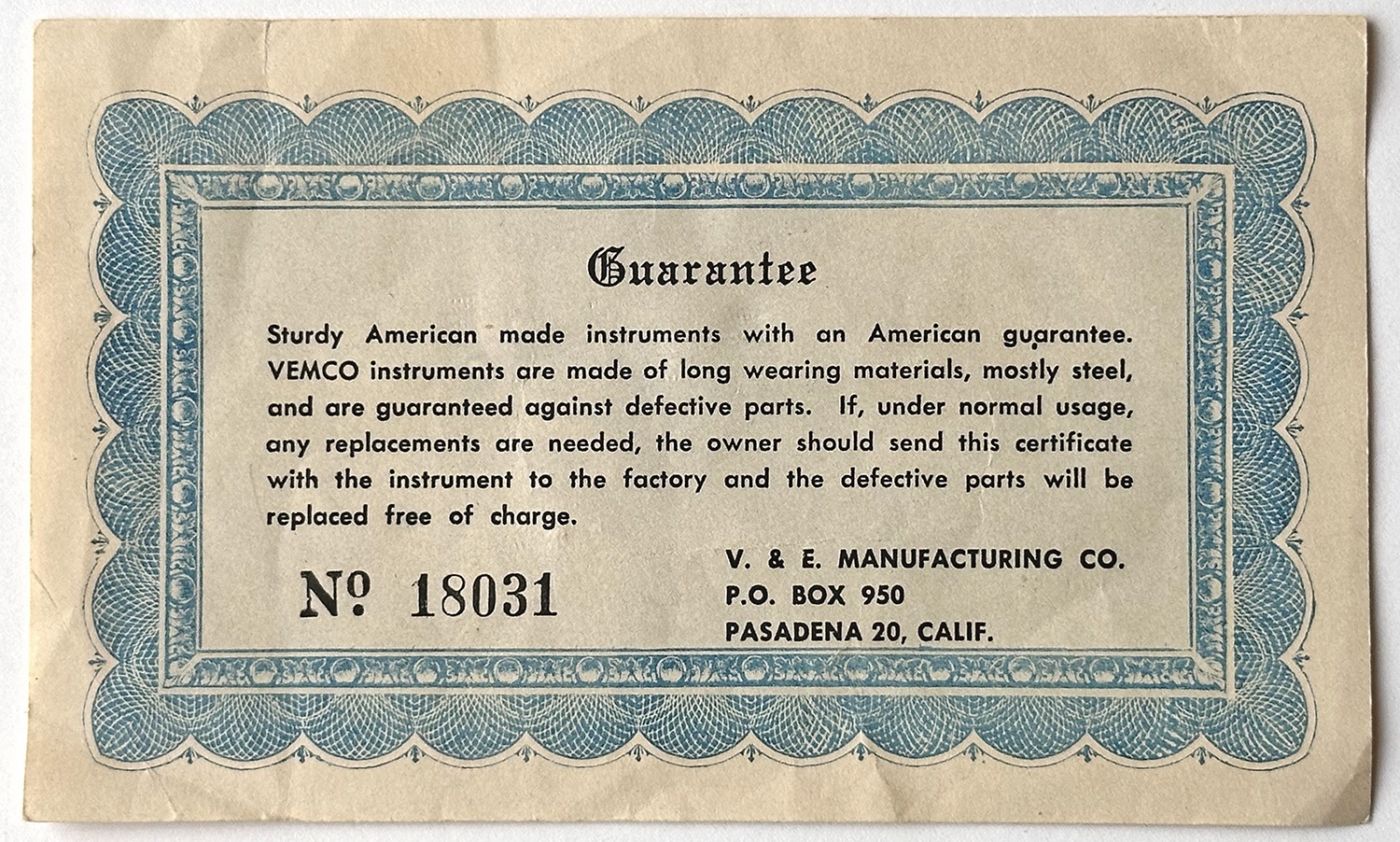

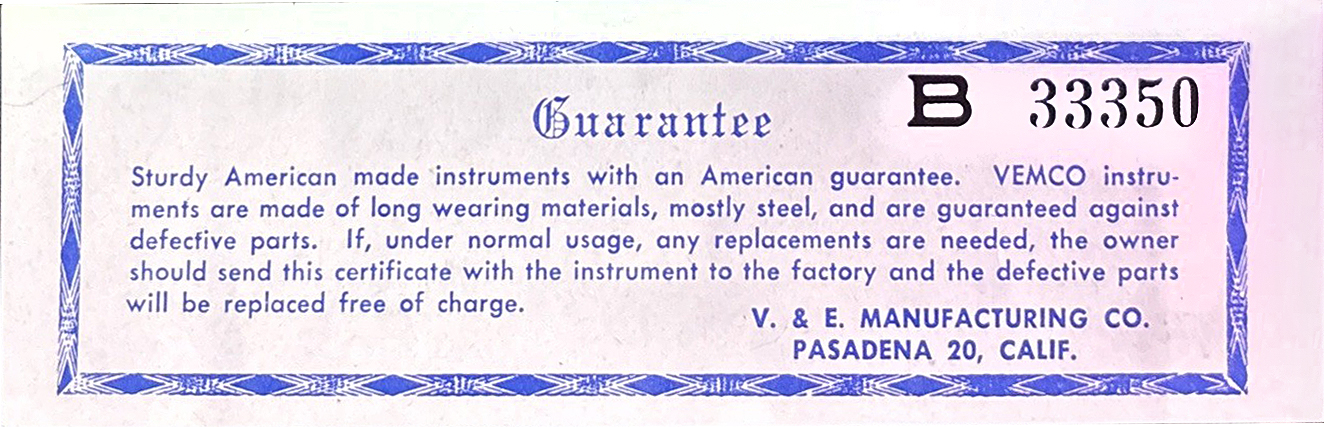

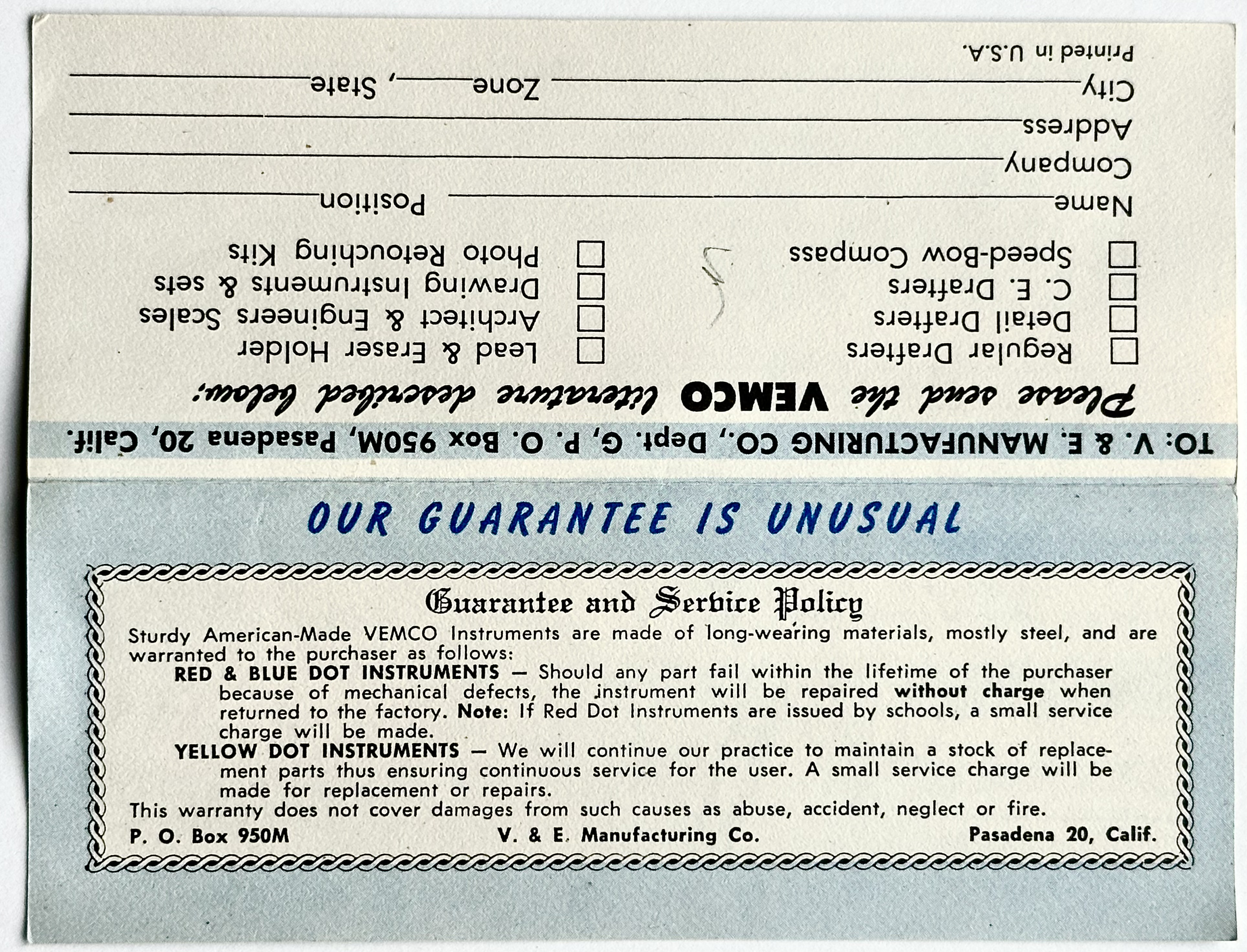

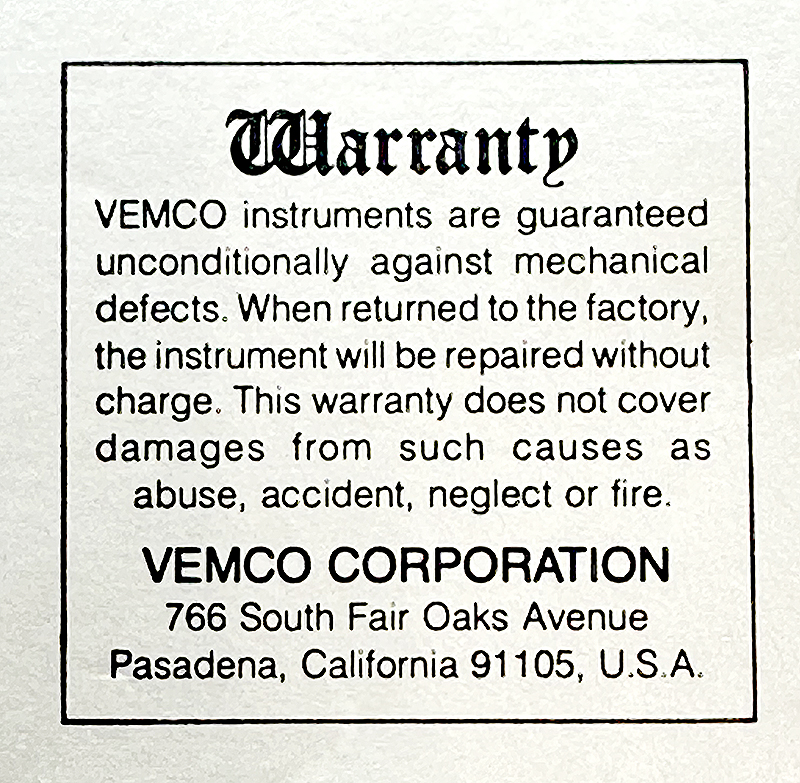

- Yellow Dot was a student grade compass made from chrome plated steel, sold at the lowest price. Repairs required a small fee.

- Red Dot was identical in construction to Yellow Dot, but sold for more and was guaranteed for life.

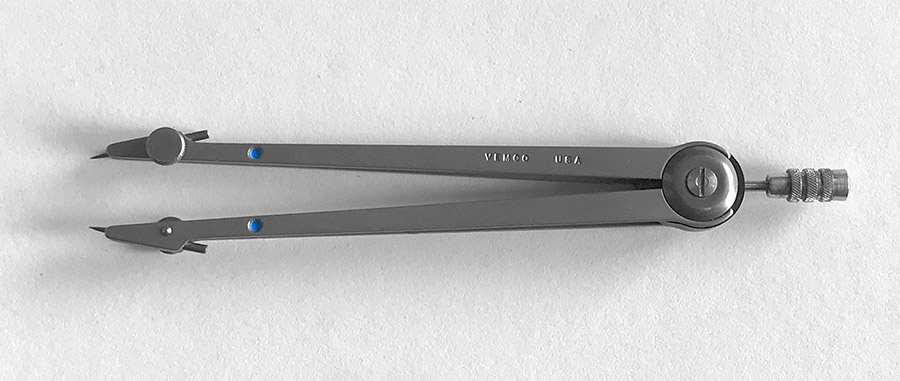

- Blue Dot was their premium line made from stainless steel and was, "guaranteed without time limit".

As can be discovered when searching for Vemco compasses on eBay and Etsy, the Yellow and Red Dot instruments often show signs of rust. This would be due mainly to the mistreatment of long unused tools that were abandoned to a basement, shed or garage for decades. One can find near-pristine versions that belonged to people who kept them in drawers of homes and offices over the years. The Blue Dot instruments, in contrast, are usually still in excellent condition to this day due to their unique stainless steel construction.

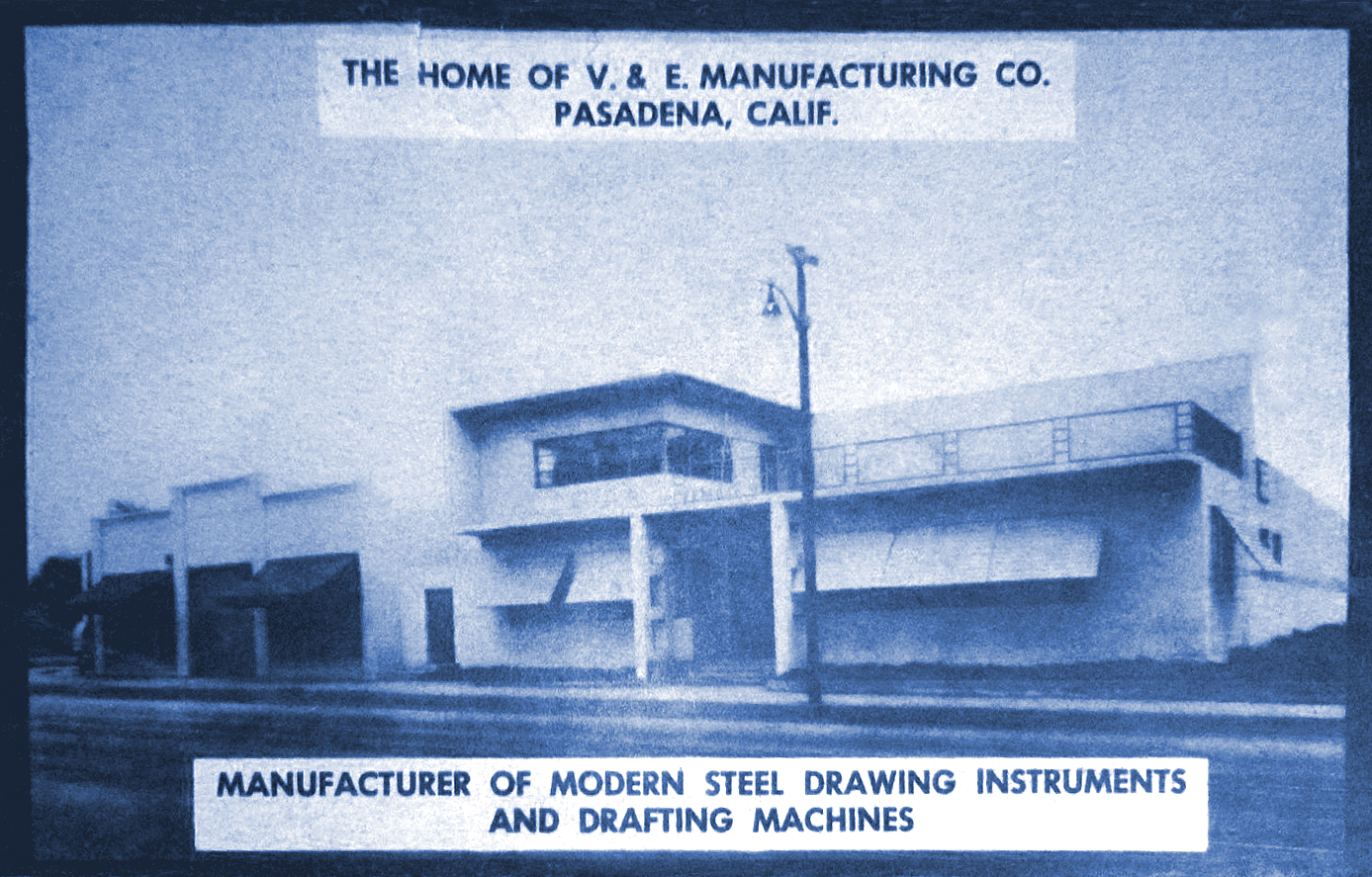

Because of WWII, VEMCO compasses became the mainstay of engineers and architects in the USA, as most other compasses were made in Germany. The truss design required less materials, which also helped in the war effort to conserve. The name "VEMCO" originates from V and E Manufacturing, founded in 1939, by Francis Vaughan & Floyd Eubanks. Dividers were also manufactured in the trademark truss design. In the latter part of the company's history, VEMCO made very elegant and streamlined versions of their top-of-the-line tools using bead blasted stainless steel. As the need for compasses and drafting machines waned due to computer aided design, VEMCO finally closed its doors in 2014.

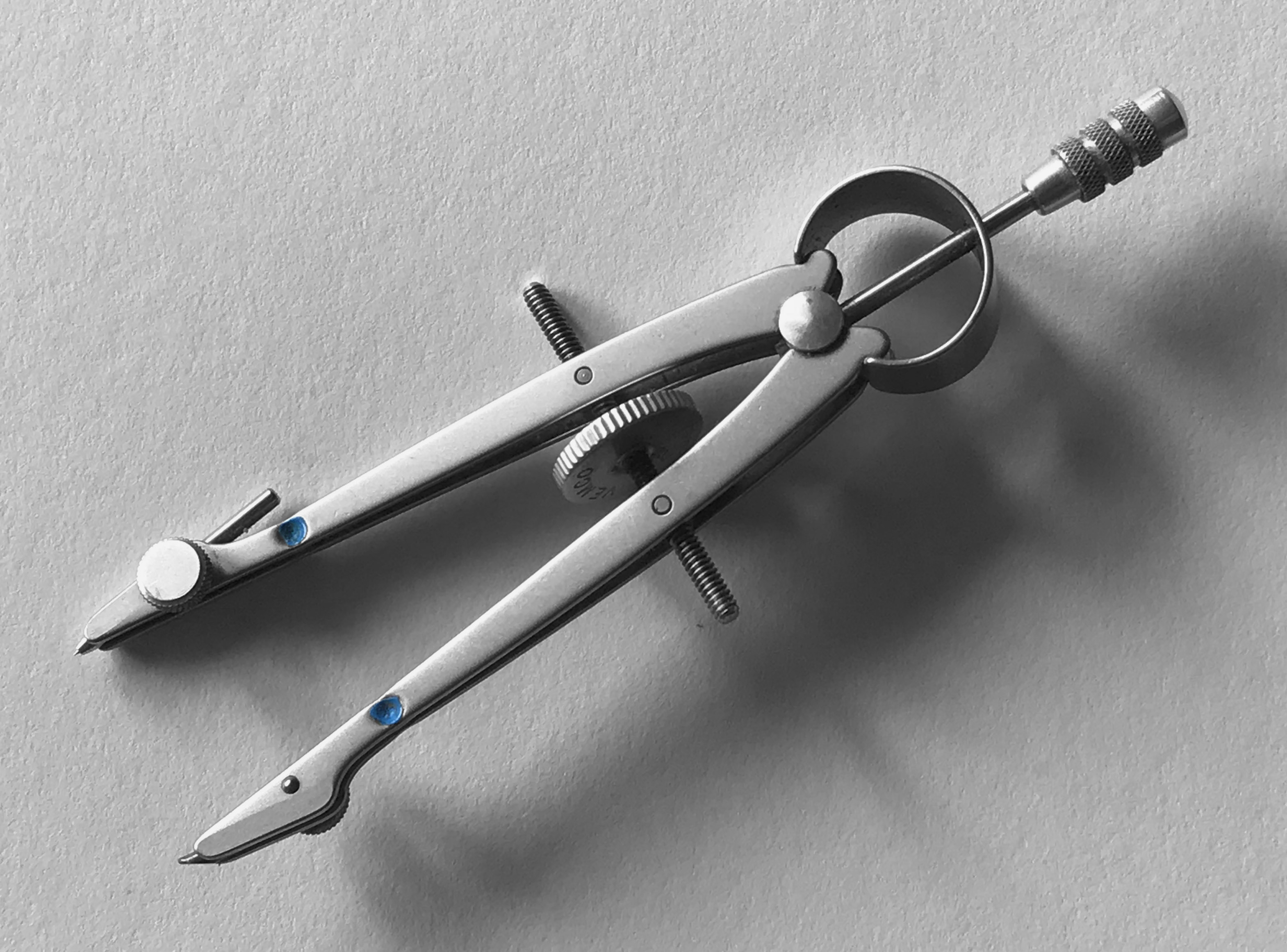

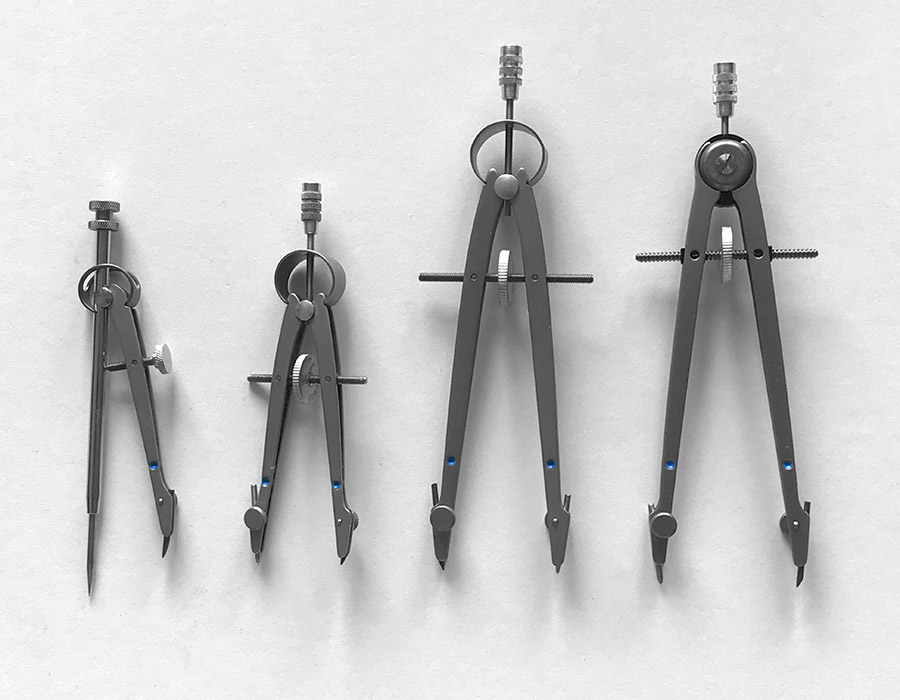

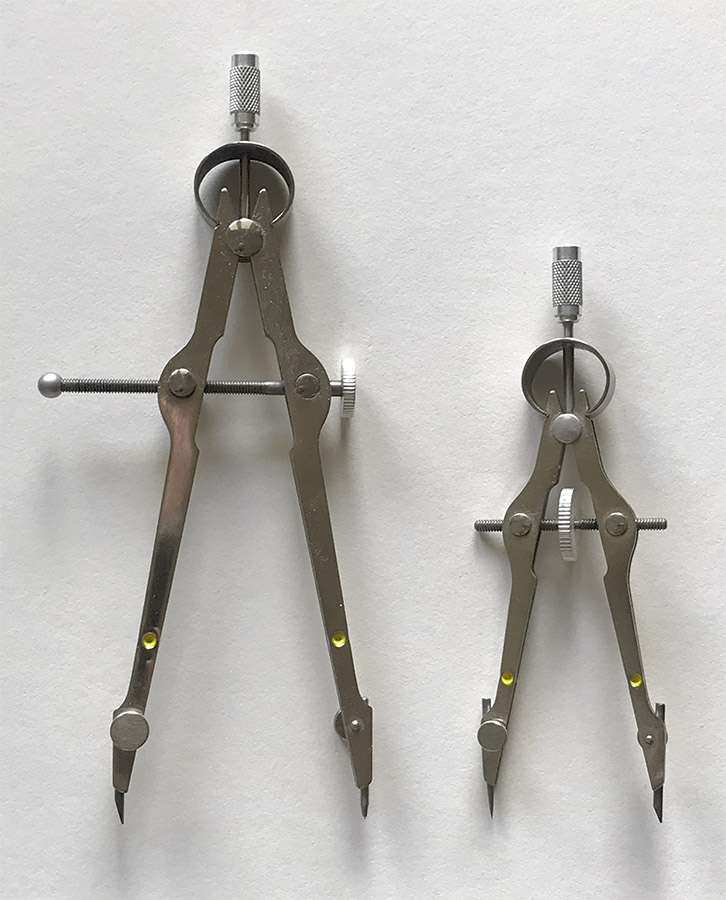

In the image, above, All four compasses are Blue Dot, produced in the latter years of the company. In this series, the compass legs were refined and simplified - removing the cutouts and contours indicative of the earliest designs (described later on this page), and replacing them with gentle curves. The curves allowed the legs to come together when fully closed while still providing clearance for the adjustment wheel. All are bead blasted stainless steel. The leg innovations allowed these compasses to draw larger circles than their original versions of the same size.

- The drop bow compass shown was specially designed for drawing very small circles. There is a pivot pin and one leg. The pin slides and rotates vertically in a shaft, allowing the drawing end of the compass to rest by gravity onto the paper. The leg is freely spun around the still pin. The diameter adjustment wheel and threads engage in an indentation on the vertical shaft for push-off. Unlike ordinary bow compasses, only one leg is adjusted. The drop bow concept was not invented by Vemco, but they applied their design ethos to this elegant version. The D-580 has a circle diameter range of 1/32" to 2".

- The small and medium bow compasses shown were the most commonly purchased, and provided a wide range of circle diameters. The 4-1/2" high S-550 has a circle range of 1/16" to 6". The 6-1/2" high L-560 has a range of 1/16" to 13-1/2".

- The speed bow compass has a unique thread geometry, allowing the compass diameter to be changed either via the wheel, or by simply pulling the legs apart. The speed bow design does not utilize a bow spring; instead, it relies on a friction mechanism similar to that found in the friction divider, described below. This friction mechanism was required because a bow spring would have constantly forced the compass open against the smooth, widely spaced adjustment threads.

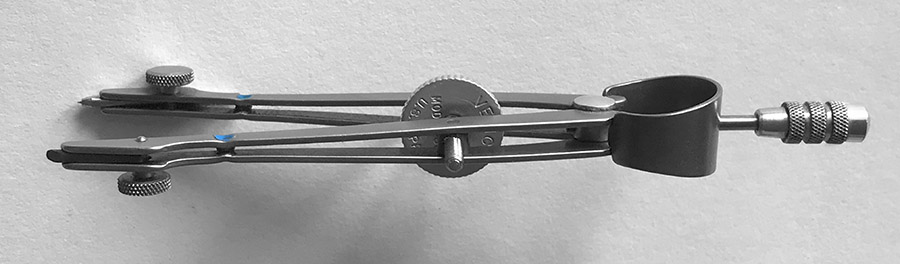

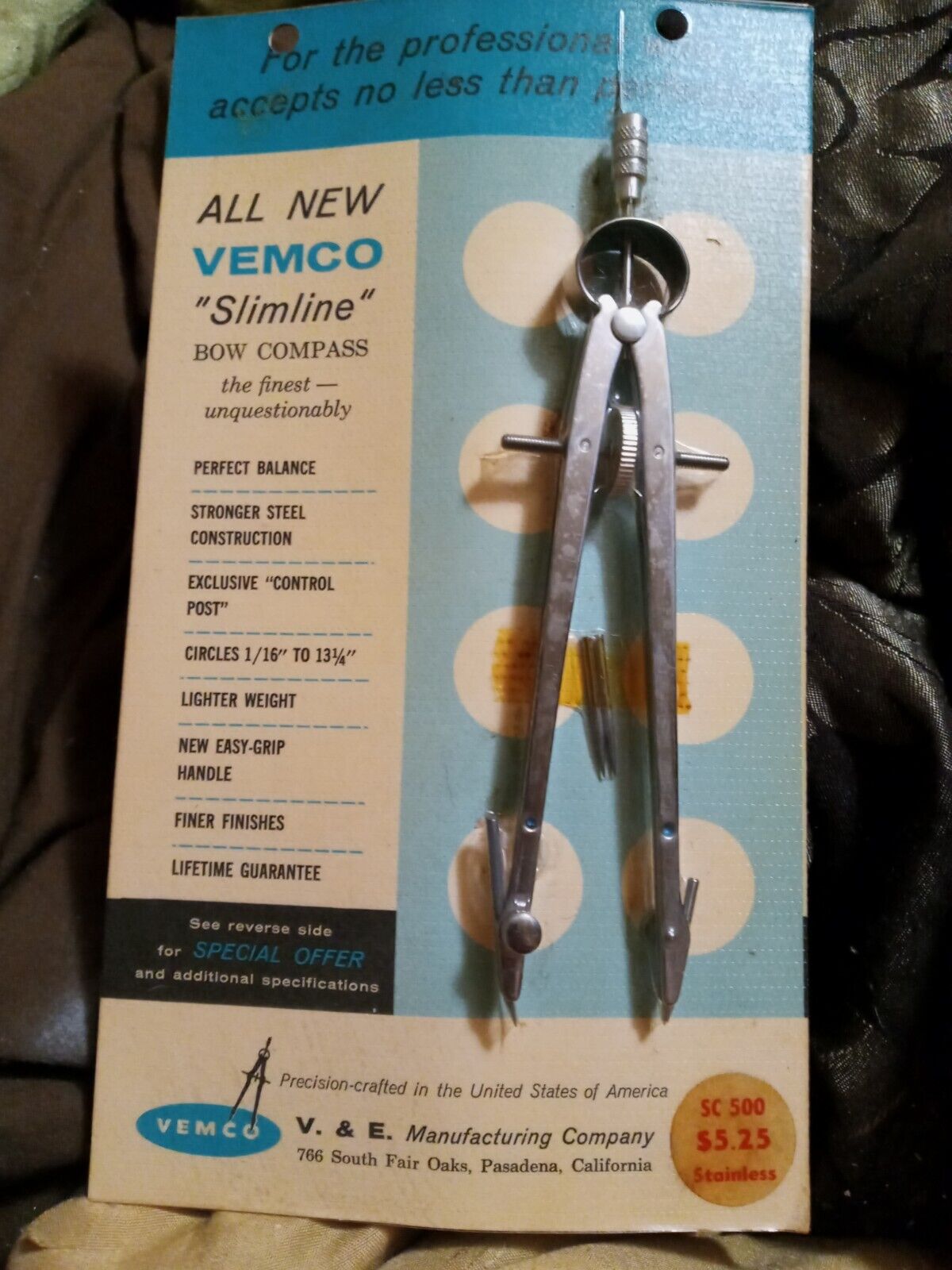

Intermediate to the transition to their final compasses, Vemco made 6 1/2" compasses called "Slimline". They predated the final versions pictured earlier, but introduced the concept of the curved and simplified legs. The Slimline design had the thumbscrew higher up on the leg, allowing for a reduction in the length of the thread portion of the compass. They were available in all three grades.

The friction divider utilized the same open truss structure as the compasses. This made for strength and lightness. There is no bow because a bow has to be sprung against the force of adjustment threads. Because the divider is not used for drawing circles, there is no need for it to be so triangularly rigid. There is a black plastic element within the friction head that provides a squeezed bearing surface for keeping the arms in their desired positions. In an older iteration - Friction Divider SF-328 - a metal element was in place, rather than plastic. That model also had deep impressions in the legs for grip. It is shown at the bottom of this page in a teal and white hanging display package.

Above are examples of the lowest tier of Vemco compasses. They are also older than the Blue Dot models described earlier. These two compasses utilize the original leg profiles described in the patents, linked below. Notice on the right compass the leg cutouts that allow the legs to come very close together by fitting around the adjustment wheel. Also, the nuts that engage the adjustment screws are much larger in these older designs. Because of these features, the compasses did not open as wide as their successors. Interestingly, the cutout leg was also employed on the speed bow, probably because the company could manufacture them with the same leg parts as for their normal large bow compass. This speed bow design employed the same type of fine threads found in the normal bow compass, and required a spring loaded disengagement button to activate the speed adjustment. The adjustment wheel could also be employed for fine adjustment. Unfortunately, the combination of bow spring and push button disengagement would allow the compass to spring violently open - thus one probable reason for the ball on the thread end.

One last note about the early speed bow design: normal bow compasses employ left handed and right handed threads. This allows the legs to move equally apart from the center, but in this speed bow design, only one leg adjusts, which is why the adjustment wheel is on the outer side of the right leg. This single-nut thread design means that the adjustment wheel opens the compass half the speed of a double-nutted compass.

Now for some pure speculation: in my own experience as an inventor, and with an understanding of the evolutionary nature of design, I can believe that the later leg design could have come from having conceptualized the original, flawed speed bow, where the designer might have concluded that the leg cutouts were unnecessary, leading further to rethinking the purpose of the cutout in future iterations, lending eventually to the curved refinement. It would be an interesting jumping off point to see if you could make your own improvements to Vemco compasses!

The various kits shown above sometimes included inking tips, inking pens, graphite sharpening sandpapers, beam compass attachments, and capsules containing spare graphite and steel points. The beam attachment allowed the standard compass to draw very large arcs. It is difficult to find complete kits for sale these days. Over time, one may be able to acquire missing parts to make up a full kit. The beautiful kit shown at the top of this page was designed specifically for the various instruments individually gathered from all over the country over the course of several years, modeled after the leather case seen in the kits above. In the Throckmorton Jones version, spare leads are stored in contemporary threaded stainless steel pill cases, as it was not possible to locate any original spare parts sleeves. Looking at the four individual packaging variations on the right in the photo above, it is apparent how large and competitive the compass market was at the time, otherwise there would not have been such a need to do so many "refreshes".

Vemco was in business for 75 years. Over that time, product design changes were made by necessity, innovation, and aesthetics. This included how the tools were packaged and displayed in stores. The Vemco logo, fonts and graphics also changed several times, most likely in a desire to look contemporary. For the discerning professional engineers and architects, kit sets were created. They varied over the years to compete with the standards of their competitors, as well as to up the ante.

Vemco Patents

It is fascinating to understand the thought processes of inventors by reading their patents. Here are some links to VEMCO's ink pen, compass, and divider patents:

- Aug. 18, 1942 - pen design patent: Des. 133,491

- Sep. 08, 1942 - drop bow compass design patent: Des. 133,698

- Oct. 06, 1942 - bow compass utility patent, where the legs are spot welded to for a truss: 2,297,999

- Oct. 06, 1942 - bow compass utility patent, where the legs are machined to form a truss: 2,298,000

- Mar. 02, 1943 - bow compass design patent, the ornamental aspects: Des. 135,138

- Jun. 15, 1943 - drafting pen utility patent, where the pen nib attaches to a compass: 2,322,002

- Feb. 27, 1951 - divider utility patent: 2,543,138

Note: a Design Patent protects the ornamental aspects of an invention. A Utility Patent protects the functional and manufacturing aspects.

Both founders were inventive, and acquired many patents. Floyd originated the VEMCO compasses, drafting machines, inking pens, and other types of devices: an apparatus for working filamentary materials, wire cutting/insulation stripping machines, wire end benders, a door lock key guide, timed electrical control apparatus, and a tooth brush with an identification strip. Francis invented the VEMCO divider, and also other drafting machines, surveying instruments, and an optical system for indicating angular deflection!

Evolution of design, as seen through other inventors' patents

After Vemco came out with their designs, other inventors followed suit. Below you can see patents that bear a direct relationship to the open truss design. The dates suggest that there was an attempt to evolve Vemvo concepts. In the reference section, Eubanks patents are mentioned. Upon examination, one can see why these new designs did not compete with Vemco. Patents don't actually guarantee improvements any more than genetic mutations are automatically improvements.

- June 14, 1947 - Alexander P. Bartusch, Lockport, N. Y., utility patent: 2,422,286

- April 11 1967 - Robert W. Selleck, San Jose, CA., utility patent: 3,313,028

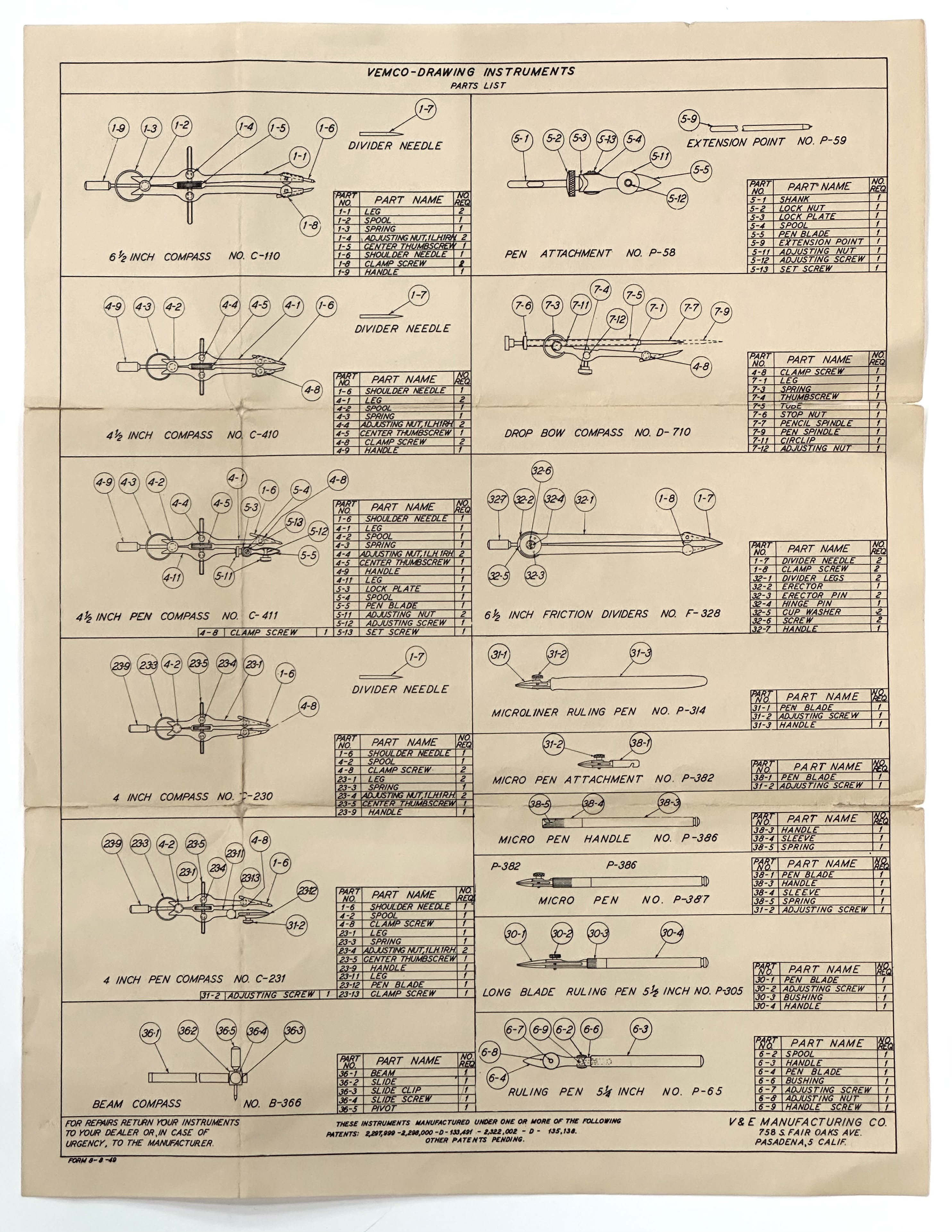

Parts List

The parts list, above, names each part of their compasses and pen instruments as of 1949. Notice the early compass designs. All of the compasses and the divider shown here were in the RED series, which were not stainless steel but still were guaranteed for life. Notice the drop bow compass has an adjustable leg (part 7-1) that has a cutout just as the other compass legs do, but that serves no purpose since the thumbscrew does not fit within this cutout. As mentioned earlier on this page, this artifact also appeared in their early speed bow compass design. The beam compass on the parts sheet is used with any of the compasses that hold the divider needle (part 1-6). The needle would be removed, and the beam compass installed; a clever way to make very large circles with the regular compass.

Available Items Sheet

Vemco made a wide range of products for drafting, and this included drafting machines, scales, compasses, dividers, pencils, and pens. This slip sheet came in boxes of individual compasses and dividers, date range unknown, but while the original leg-style compasses were in production. On the reverse side is "Our Guarantee is Unusual", and a form for receiving product literature.

Point of Purchase Display

In some cases, boxed compasses came with the addition of a "point of purchase" display panel that could be set up as shown. The POP display described the unique features of the Vemco line. In this example, the 40-C Yellow Dot compass was on display.

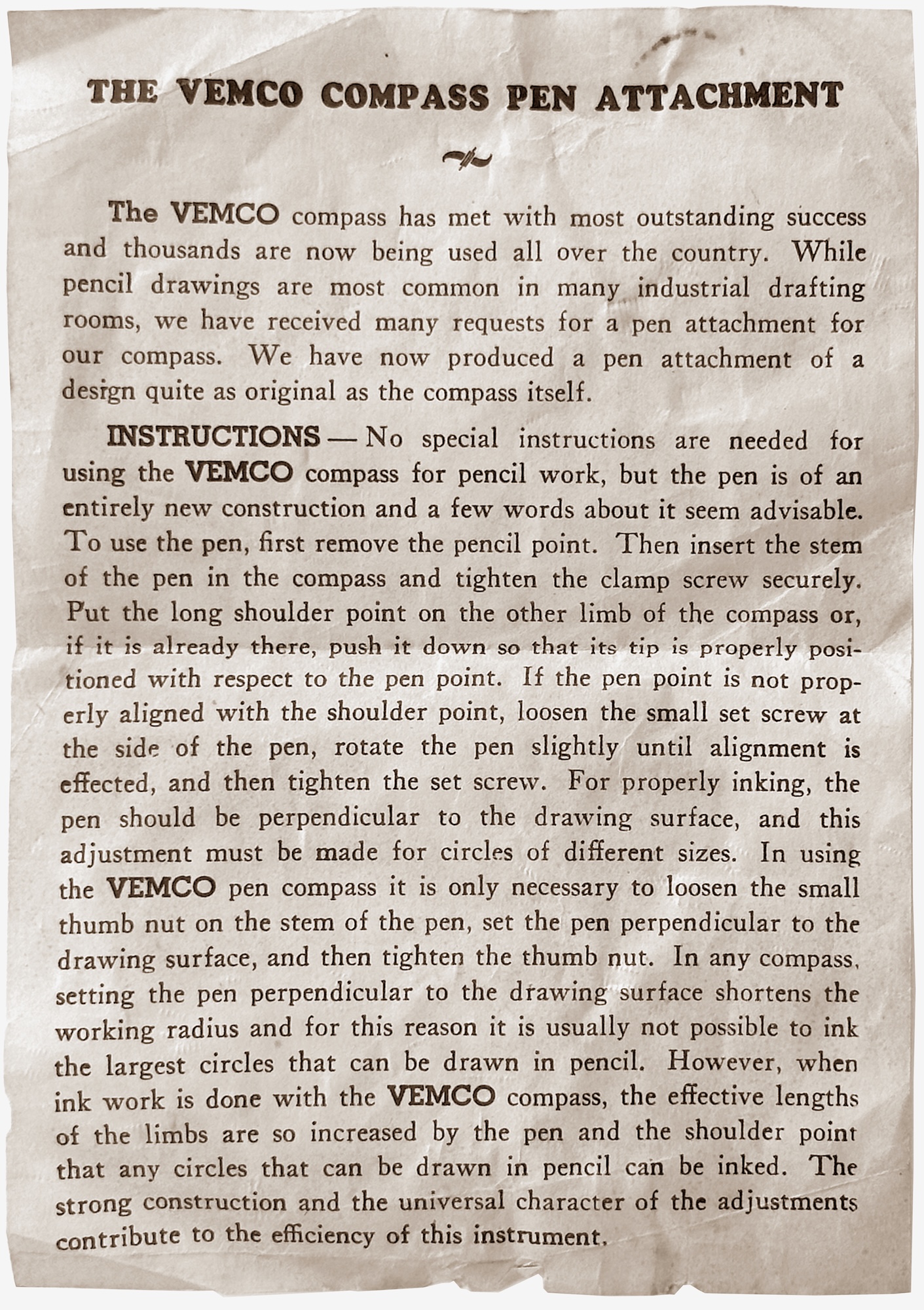

Compass Pen Attachment Instructions

Ink was the standard drawing medium for many centuries because of its clarity and permanence. Around the time that Vemco started their company, drafting shifted from predominately using ink to using pencil. This was possible because of improvements in pencil technology, allowing for greater tonality variations, sharpeness, strength, and adhesion to paper. Because of these improvements, Vemco created compasses exclusively for use with a graphite pencil point.

In 1943 upon request from those who still needed to ink their drawings, the company created a special pen attachment that could turn their compasses into inking compasses. This required two parts to function: the P-58 Compass Pen Attachment, and the Extension Point P-59. When assembled, the compass looked quite different. The pen attachment and extension point needed to be set so they were protruding the same amount, and the inking nib had to be set perpendicular to the paper surface for proper inking.

Guarantees and Warrantees