Interlock Design

An interlock is the portion of the module that allows a tab to fit into a slit or slot, thus keying modules and even extensions to one another. In the simplest iteration they are located along the base polygon's edges. A good interlock is able to connect solidly while also being a part of the aesthetics of the lamp.

Basic Engagement of Modules

The simplest way to engage two modules is to make a single slit cut to the mid-point of a module's base polygon's edge. This cut allows modules to slide together and form a basic interconnection. This is not robust, as the two modules can easily become misaligned and separate.

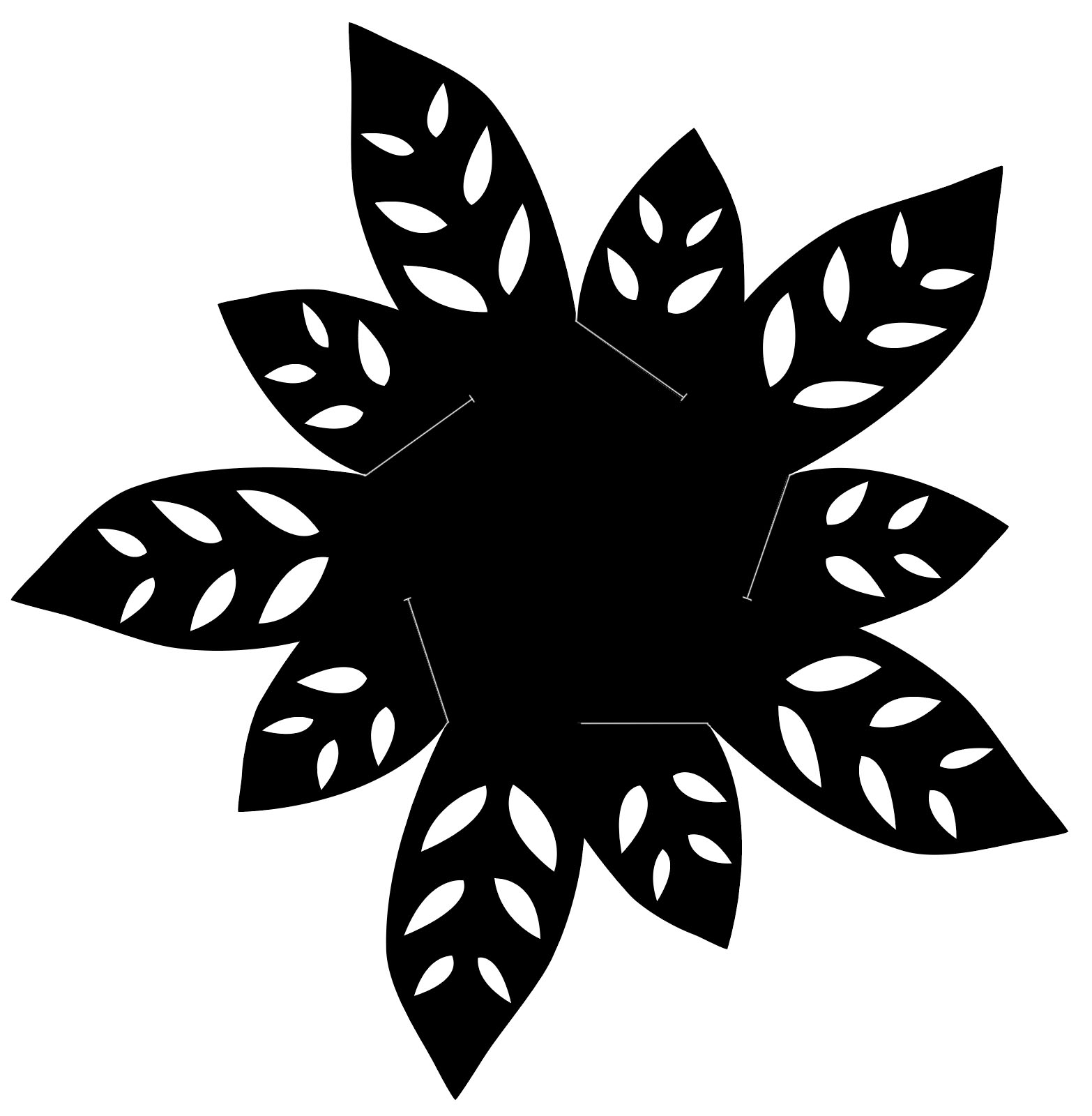

Above is an image of a simple slit cut module. The slit also has a small perpendicular relief cut at its closed end that does several things: the relief cut acts as a positive stop when engaging another module; it can prevent the slit from tearing further along its length in easily torn material; and it allows the module to part like a flap when another module is engaged.

Above, two identical modules slide together to engage them, forming a connection. This is the basic process by which modules will be engaged forming the lamp structure. As described earlier, the simple nature of the slit without incorporating interlocks makes the assembly vulnerable to coming apart or getting tweaked out of alignment and opening gaps. Jostling or bumping a lamp designed this way is all it takes for the system to fail. In fact, the weight of material alone on a larger lamp will cause the connections to slip. In general, a lamp that is built only with simple slit cuts tends to look imprecise.

The Interlock

It is much more robust to add interlocks, either at the slit zone or within circumvolutions, that pin the structure together. Deciding where to place interlocks has to do with analyizing the shape of your extension, and how far it projects along the polygon's boundary. If your extension runs the full length of the polygon's edge, the interlock location can be further out, making the length of the extension more solid. But it cannot be at the end of the cut or the interlock will be loose. If the extension width is small, the tab must move closer to the centerpoint.

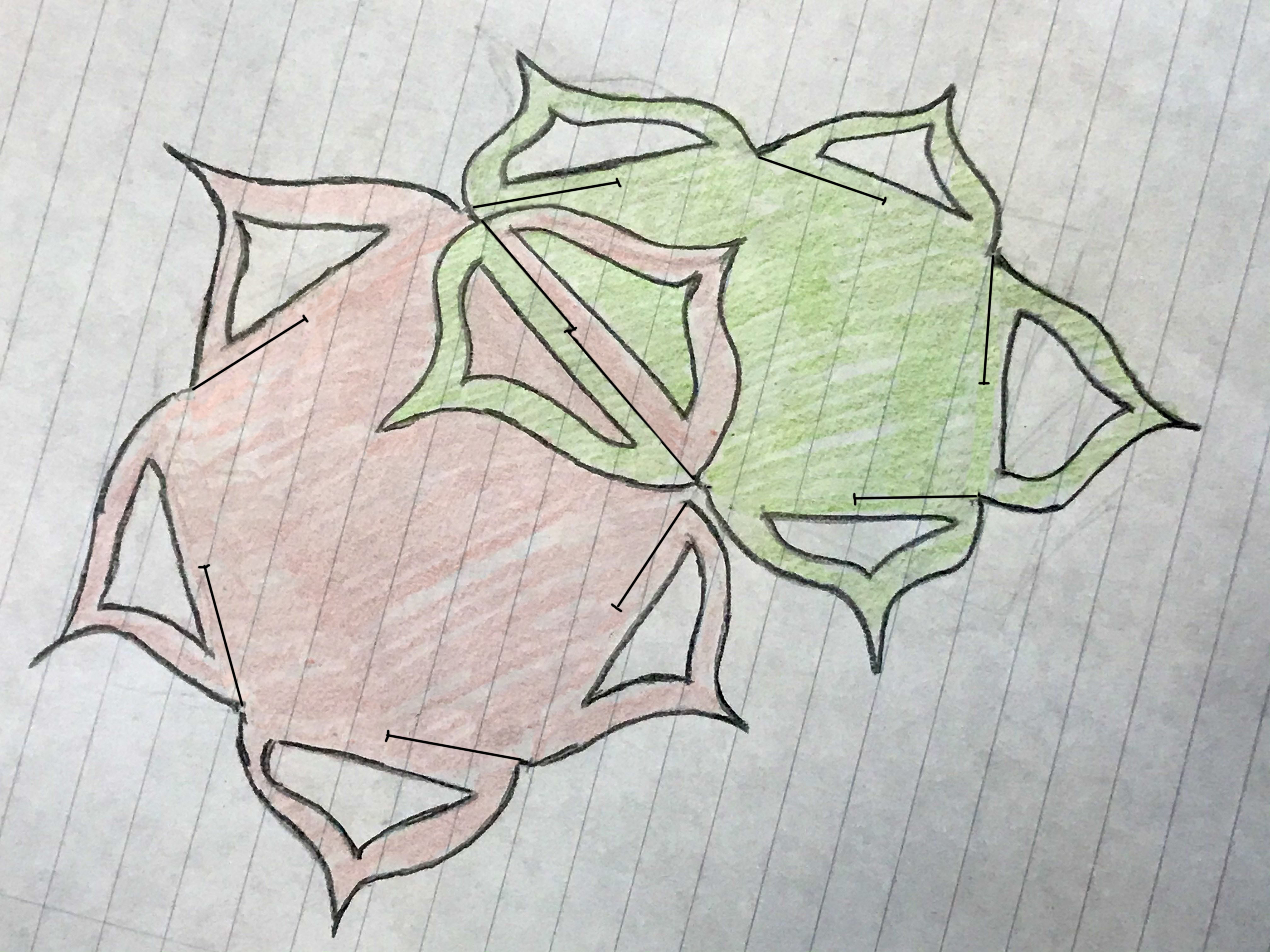

For fit and finish, it is important to locate the interlock as far away as possible from the centerline of the polygon's edge to create a tightly enclosed volume - and with a big enough gap from any nearby cuts to maintain strength. In the image above, the green dotted line represents the center axis of the polygon edge. The slit cut that is used to interconnect the modules terminates here. Then the slot of the interlock is positioned some distance away from cuts or edges. Its location dictates the location of the tongue. Both the slot and the tongue are equally distanced from the center axis line because when an identical module is engaged with another, the tongue of one aligns with the slot of the other, and can be plugged in.

In the above image, notice the subtle difference in the use of a slot in the zoomed-in view, and the use of slits with relief cuts in the three other views. Read more on the subject, below.

Slit Versus Slot Cuts

A choice between making just a clean slit into the lamp mateiral versus making a more complex slot cut has to do with the tools used for the work, the thickness of the material, and the dihedral angles between mating modules.

Slot Cut

Slots can be created by making two parallel cuts with a knife, then trimming the material out. It can also be automatically cut with a laser. In fact, a laser cutter cannot make a slit cut at all; only a slot, albiet small. The typical laser cuts a kerf of 0.25mm as a basic single-pass cut. If you need a wider slot than that when using a laser cutter, it needs to be designed into the vector file. As seen, when penetrating the material at 90°, a narrow slot the thickness of the material (minimum) needs to be made. When expecting a raking angle is needed, the slot must be cut wider to accommodate the passage of the material undistorted. Of course, you can plan to make a smaller slot width if distortion of the connection is unimportant, or even desired.

Slit Cut

Slit cuts do not work with 90° connections because the material simply cannot pass through well enough to maintain a 90° angle. Other angles will easily pass through the slit, if relief cuts are also included. If you do not inculde relief cuts, the closer to 90° one goes, the more stress is applied to the materials. If relief cuts are not desired, consider lengthening the slit to make the fit looser, though this does introduce side-to-side movement to the inserted piece.

Relief Cut

For very thin materials, it may not be necessary to make relief cuts. For example, in my video demonstration at the bottom of this page, I make a set of modules that have interlocks without relief cuts becuase the prototype is made from thin paper. If I would be making the lamp from a thicker or difficult to flex material, the relief cuts would make a huge difference in ease of assembly. As described earlier, the purpose of the relief cut is to allow flex in the connection point, which implies that there is no need to make relief cuts if the material easily flexes, or if you chose to make slot cuts instead.

Dimensions and Direction

There are practical and aesthetic reasons for determining the depth and width of the interlock. The most basic is structural: will the tongue be strong enough not to tear? If it is too narrow, it may easily tear. Will it go deep enough to keep in place? A shallow tongue will disengage easily. Lastly, does it look good in my design? Sometimes the visibility of the interlock enhances a design and sometimes it is a distraction.

When using Warlon or Syskin, the tongue width should be somewhere between 3/16" and 3/8" (5-10mm). If the lamp has small modules, smaller tongues are appropriate. Conversely, larger modules justify larger tongues. If you use polypropylene, such as Yupo, it may be possible to make smaller-width tongues, as long as the material is every hard to tear. Warlon is difficult to tear if inside corners have small radiuses, but is easy to tear if a corner has any nick in it whatsoever. Because Warlon is easy to tear along an existing cut, adding a relief cut to the initial interconnection slit helps prevent accidental tearing along the initial interconnection.

Slot and Slit Width

The slit cut that engages the tongue (or slot cut) needs to be perhaps 1/32-1/16" (about 1mm) wider than the tongue to make insertion easy. If your slit design is just a little oversized, there will be less risk of assembly problems such as tearing, misalignment, or trouble engaging the interlock. But don't make the overage too big, or the joint will be loose and the lamp may begin to look misaligned.

Tongue Design Problems

As shown in the diagram, above, there are many ways to cause an interlock to either come apart unexpectedly, fit poorly, tear apart, or be difficut to assemble.

Tongue Variations

The diagram, above, shows five variations in the tongue design. All of them will function well, but there are some notable differences in what they do best. The tongue facing in holds the extension in place very well. The tongue facing out allows the extension to be floppy, while engaging the base polygon very well. The one with the S-shaped tongue engages both the extension and the base polygon equally. And finally, the two versions of the barbed tongue locks the extension firmly in place, making it impossible to pull out without damage. To engage a barbed tongue you must fold or bend the barb over so it faces inward, allowing tongue to be inserted. Then the barb can be opened back up.

Circomvolution Example

In the creation of a circumvolved lamp, another type of interlock and interconnection has to be designed. In the example, above, the extensions have slits cut into them that mate with the center area of their neighbor modules, but they do more than that. They also pass through the edges of their cohorts that also connect at the center. Notice how the center cutouts include a small extra slit cut: this cut is necessary because the circumvolution tab is actually a little bigger than the slit that fits over it. This means that it take effort and a little cajoling to get the two together, but once they do, they forcefully lock together, making it very difficult to take apart. it is like a barbed thorn. or a felting needle.

Demonstration Video: Interlock Design

10-1/2 minute video on using a story pole to design and lay out an interlock.