Calder-Related Materials

Making work that takes on the qualities of Calder means finding a range of materials, both new and old. It is possible, under the right circumstances, to have everything you need already on hand. However, if you don't tinker with wire, sheet metal, wood, paint, fabric and glass, you may need to search for supplies.

Alexander Calder played with many media, from painting, printmaking, textile design, drawing, and any other 2D process he found interesting. He also worked in - and even invented - a wide range of 3D styles. He experimented with wood carving, metal casting, mobiles, stabiles, jewelry, wire portraits, and mechanical toys. He even designed sets for ballet and dance performances, created massive sound baffle designs for performance halls, and painted patterns on full-sized passenger jets. The scale of his work ranged from that which hangs on the tip of a finger, to objects rivaling multi-story buildings.

His work and drive to create was vast, which meant that he tried everything. He had few limits to his interests or creativity. How do we narrow down media to what can be accomplished in a class project? You will produce a wire portrait and a mobile. These two projects utilize simple, hand-manipulable materials that can be cut and shaped with common tools. These tools are described on other pages, but the materials can include (and are not necessarily limited to):

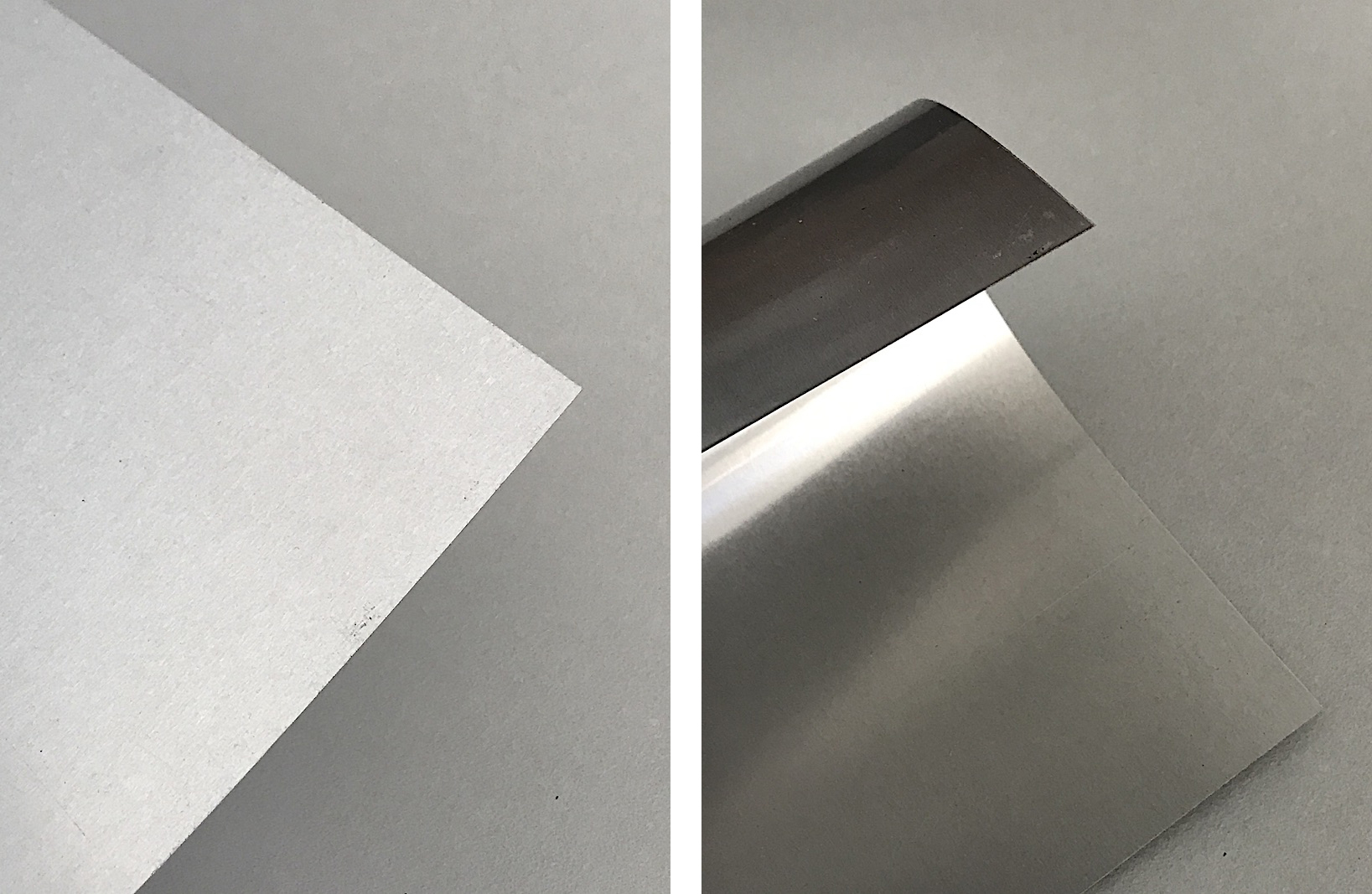

Above are examples of aluminum flashing aquired from a local hardware store. It has a brushed finish. One side appears glossier than the other, so it must have a clear coating on that side. It is springy, so it is hardened. A caliper reading shows that it is 0.008" to 0.009" thick, or 8 - 9 thousandths. This is equivalent to 31 gauge non-ferrous metal sheet. 80 LB Brisol paper is 10 thousandths (ten thou) thick.

About flashing, primarily aluminum flashing

- Flashing is readily available at hardware stores, cuts easily with scissors, and has a large surface area to thickness ratio. It is appropriate for mobile airfoil elements. Because aluminum flashing is lightweight, it is ideal for making things that hang from a ceiling or above your head.

- The term, "flashing", refers to any thin material that is used in construction to prevent the passage of water at transition points on buildings.

- Hardware stores can have flashing made from a wide variety of materials, including aluminum, galvanized steel, and plastics. Copper , lead, brass, and zinc are also found in flashing form, but are specialty items. None of these are appropriate for a mobile due to weight. Be careful not to mistake galvanized steel for the aluminum. It is significantly heavier, and more difficult to work.

You may not have a choice in what you find, but their properties are noticeable. Manufacturer reps sometimes cannot even provide information of what types of aluminum flashing is sold where, or to even be aware that there are physical differences in their products. Here are some qualities of aluminum flashing you may encounter:

- plain (no coatings)

- coated (with a clear finish to prevent oxidation - you may not know this is there, other than an unusual smooth feeling, or a different kind of shininess on one side). Care must be taken when heating coated metal because it will produce a terrible odor, and will discolor to a caramel brown to uneven black.

- anodized one side (may look like artificial brass or gold)

- hardened (this feels very springy, and if you took one corner and bent gently with your fingers, it would snap back, best for maintaining a dent-free piece)

- dead soft (this can be easily bent by finger pressure on a corner, and the bend would stay in place, ideal for projects where deformation of the sheet is important)

- very thin or heavier gauge (this information may not be listed on the product)

- mill finish (no parallel scratches)

- brushed or sanded (with parallel scratches all along its length)

Wire or rod

Above is welding rod purchased from a local welding supply shop. The metal is called R45, which is not of importance here, but means it is a certain alloy of steel. It has a very thin copper plating. The upper piece is 5/32" dia. The middle one is 3/32". The lower one is 1/16". Notice the stamped portion. The rod itself is rigid, but can be bent, but where it was stamped, it has been so work hardened, that if you try to bend the portion, it will likely snap in half. The stamped portion should be removed or annealed.

Using rigid steel wire (rod) of various gauges or diameters:

- This rod is commonly used vertically, diagonally, and horizontally to hold elements apart, and to define form.

- Rod versus Wire: Wire typically is flexible and can be easily coiled. Rod is typically stiff, and sold in straight sections. We are really after rod, rather than wire, but the terms are often interchanged.

- Rod comes in every type of metal, but for our project, steel is the most useful, and also least expensive. Typically, we use welding rod because it is available at local welding supply houses and comes in a range of diameters. "Gauge" is a typical form of diameter measurement for rigid wire/rod, except at local hardware stores and welding shops, because they come in fractional inch-increments. 1/16" is usually the thinest, followed by 3/32", then 1/8", 5/32", and 3/16". Larger sizes usually are not sold as welding rod, but are available as raw material.

- Anything larger than 1/8" is pretty difficult to cut with hand-held nippers and diagonal cutters. Instead, they are best cut with a hack saw.

- 1/16" and 3/32" can be curled into loops with relative ease, but larger diameters than those become difficult to bend in small loops.

- Stainless steel and aluminum are also easily found, but are usually more expensive. Stainless steel is ideal for outdoor use. Steel will rust, and should be painted anyway. Aluminum may be too malleable, and if hardened, may be brittle.

- Steel welding rod is typically coated in an extremely thin copper layer to keep the steel from oxidizing. Do not mistake the rod as actual copper. It will still rust, if exposed to moisture, and scraping or sanding lightly will remove the copper easily.

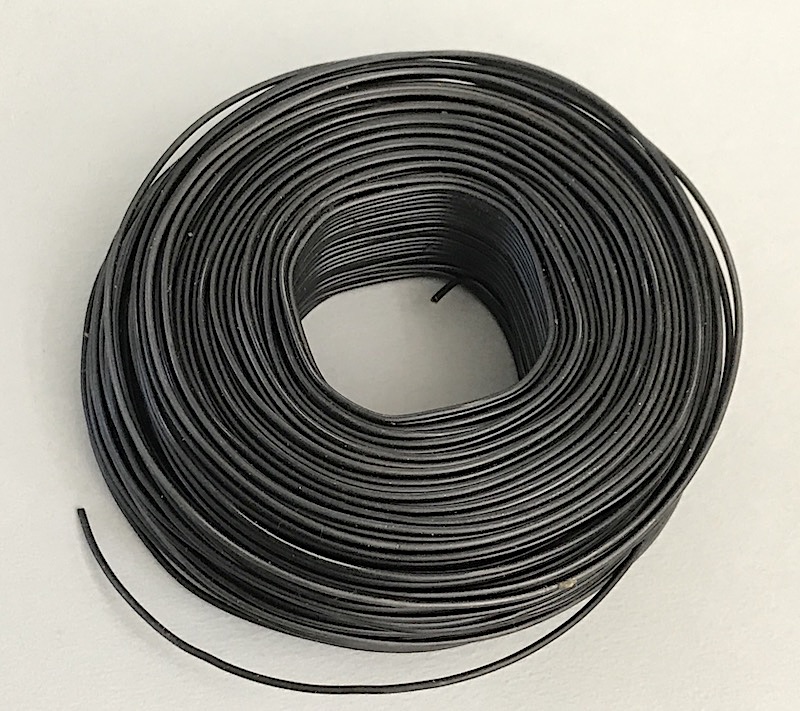

Tie wire

Black steel tie wire can be found at most local hardware stores. It is coated with either oil or a fine grease, but bonded fairly well. Notice that it is slightly shiny. Not all black tie wire looks like this. It may also look a little duller. In the duller case, the black rubs off easier. Hands become very dirty when working with tie wire. Notice the rectangular form in the center of the spool. That was formed by the mandril it was wound on, and indicates the softness of the wire to deform. Also, once you get down to the core of the spool, the wire is more wavy, and less pleasant to work with.

Soft malleable black steel tie wire, 16 GA to 16.5 GA is common. This is used often for loops, hangers and vertical members in mobiles, and is the only material needed to produce wire portraits.

- Tie wire is simply a common term and readily available form of wire that is easy to bend, and is used in the construction industry to tie rebar together. Otherwise, it is just wire.

- It is usually black, because that is a product of the production method, and also has a thin oil or grease coating to keep it from immediately forming rust. Over time, it will rust.

- There are other versions of tie wire out there, or wires for different purposes that look like a similar diameter. Keep away from galvanized or silvery looking wire, as it does not work well for portraits due to its reflectiveness and lightness. The contrast of black is what makes the line readable. These other types of wire finishes can be used if the finished piece is painted black, or if it is displayed against a dark background.

- There are other gauges of black tie wire available. Thinner wire is easier to manipulate, but is usually too thin for a wire portrait. Also, it is much more fragile, and a portrait can easily be bent out of shape.

- Avoid stranded wire. This is specifically made for the purpose of flexibility, and the portrait needs to be robust. Also, tiny strands can easily prick a finger.

- Annealed aluminum makes a fine wire for portraiture, other than a few properties and concerns. If bent a few times, it may become rigid, fatigued, then break. It is bright, and should be painted black. If the aluminum is as thin as tie wire, it is usually very easy to crush and misshape. If it is larger in diameter, it may be too chunky for fine line art. It is more expensive than steel tie wire.

Other appropriate materials

- Braided thread, strong enough to keep from breaking by hand. Typically used as vertical elements in mobiles.

- For thread that is not already black, it can be easily colored with a magic marker or ink.

- Look for braided fishing line, upholstery thread, or leather-working thread.

- Learn to tie strong, minimal-looking knots that will not slip.

- Brushable paints, typically black, red, yellow, white, or other appropriate colors. Calder rarely left metal un-painted. Black was his favorite. For thin lined elements, black shows off very well, in the way an ink drawing appears on white paper. Thin-bodied acrylic, gauche, model paints, and and even oil paints can be used.

- Spray paint is a common medium, but requires a lot of space and care to do a good job.

- Proper metal prep is essential to producing a good-looking, and durable paint finish.

- Heavy-bodied paint has the problem of leaving a lot of brush texture on the surface.

- Paint must be left to dry and then cure properly before handling. Curing takes quite a while, long after the paint feels dry. Before being fully cured, the surface can be very fragile and easily braided, peeled, or scratched.

- Pieces of wood, either shaped by hand or naturally worn by water and wind. Can be used for a stand, or as volumetric elements in a mobile.

- Wooden dowels, bamboo skewers, or other long and rigid plant-based materials that can be self-supporting. These can substitute for rigid steel wire in a mobile.

- Broken colored and clear glass pieces without sharp edges. Can be effective in mobiles, if used well.

- Thin plywood, cut to various shapes. Can substitute for aluminum flashing.

- Wooden balls, cork balls, or pingpong balls. These can be used to create more massive appearing volumes to balance against other forms both physically and visually.Rigid matboard or cardboard, which can substitute for aluminum flashing or wooden elements to create airfoils.

- Various, readily available glues or adhesives, if needed, appropriate for the specific media listed above.

- Fishing swivels, if you desire full rotation of objects. Keep in mind that mobiles often work best by limiting the rotation of certain elements, allowing for cascading movements.

DO NOT USE:

Don't employ these materials or objects with a lot of ego or competing aesthetics that distract from the aesthetics of the artwork.

- Plastics

- Electronics

- Bullets, cans, water bottles, or other recognizable human made found objects except for spheres. Spheres appear as circles from any direction.

- Pictures

- Objects cut out to look like characters, letters, stars, moons, regular polyhedra, or other common symbolic forms.